Description

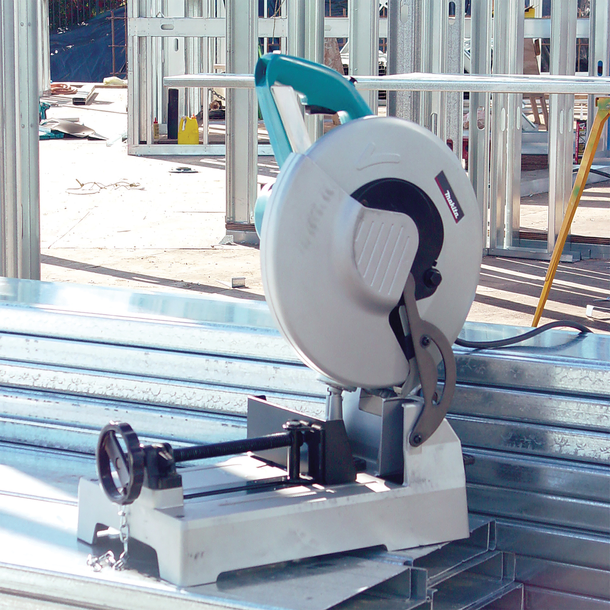

Makita LC1230 Cut-Off Saw: Precision Cold Cutting for Metal Fabrication

The Makita LC1230 Cut-Off Saw is a heavy-duty, corded stationary saw specifically engineered for fast, clean, and accurate cutting of various metal materials. Unlike traditional abrasive chop saws that create significant heat and sparks, the LC1230 utilizes a specialized TCT (Tungsten Carbide Tipped) blade to deliver "cold cuts" that are virtually burr-free and produce minimal sparks. This makes it an ideal tool for metal fabricators, pipefitters, electricians, and general contractors who require precise, safe, and efficient cutting of steel, aluminium, and other common metal profiles and pipes.

Features

- Powerful 1,650W (or 1,750W in some regions/listings) Motor: Delivers robust and consistent power, specifically geared for the demands of cutting through dense metal materials efficiently. Available in both 110V and 240V versions to suit different site power requirements.

- Low No-Load Speed (1,300 RPM / 1,700 RPM in some regions/listings): The lower rotational speed, compared to abrasive saws, is crucial for metal cutting with a TCT blade. It minimizes heat buildup, prevents material hardening, and contributes to longer blade life and cleaner cuts.

- Large 305mm (12") TCT Blade: Designed specifically for metal cutting, the carbide-tipped blade provides exceptional durability and a much longer lifespan (often quoted as 50x longer) than abrasive discs. It produces clean, accurate, and virtually burr-free cuts.

- Excellent Cutting Capacities:

- Max. Cut at 90°: 115mm (4-1/2") round pipe, or 75mm x 150mm (3" x 6") rectangular/square profiles.

- Max. Cut at 45° (Mitre): 90mm (3-1/2") round pipe, or 85mm x 85mm (3-3/8" x 3-3/8") square profiles.

- "Tool-Less" Adjustable Quick-Release Vise: A key feature for productivity. The integrated quick-release vise allows for rapid and secure clamping of workpieces, facilitating fast, repetitive cuts. The "tool-less" guide plate/fence adjusts easily from 0° to 45° for quick and accurate mitre cutting.

- Dust/Chip Collection Tray: Efficiently collects metal chips and debris during operation, reducing mess on the job site and contributing to a cleaner and safer working environment. The tray can be easily dismounted for waste disposal.

- D-Shaped Handle with 2-Finger Trigger: Provides ergonomic comfort and control during operation, reducing user fatigue.

- Lock-Off Function (or Lock-Off Button): A safety feature to prevent accidental start-ups of the saw. (Note: Some newer "N" variants, like LC1230N, might have removed the physical lock-off button due to legislative changes, relying on a two-stage trigger pull for safety).

- Large, Durable Aluminium Base: Provides excellent stability during cutting operations, crucial for precision and safety when working with heavy metal pieces.

- Shaft Lock: For easy and secure blade changes using the supplied socket wrench, which can often be stored conveniently on the base.

- Double Insulation: Offers an essential layer of protection against electrical shock, enhancing user safety, particularly on construction sites.

- Heavy-Duty Construction (approx. 19 kg / 41.9 lbs): Its substantial weight indicates its robust build, providing stability and durability for industrial use.

Applications

The Makita LC1230 Cut-Off Saw is a specialist tool invaluable for precision metal cutting in various professional settings:

- Metal Fabrication Workshops: Cutting steel, aluminium, and other metal profiles for fabrication, welding, and assembly.

- Electrical Installation: Cleanly cutting conduit, trunking, cable trays, and threaded rod.

- Plumbing & HVAC: Cutting steel pipes, copper tubing, and ventilation ducts without sparks or burrs.

- Construction Sites: Ideal for accurate and safe cutting of structural steel components, rebar (with appropriate blade), and various metal sections on site.

- General Engineering: Any application requiring precise, repeatable cuts in metal where conventional abrasive saws are too messy or hazardous.

- Reduces Hot-Work Permits: Due to its "cold cut" method (minimal sparks and heat), it often reduces or eliminates the need for hot-work permits on regulated sites, a significant safety and efficiency advantage.