Description

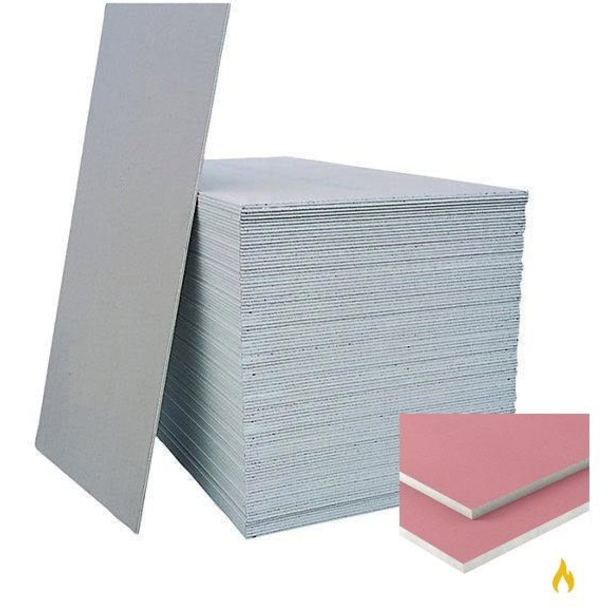

Gypfor Fire Resistant Tapered Edge Plasterboard (Fire Panel) - 12.5mm 8x4ft

Enhanced Fire Protection for Critical Applications

Gypfor Fire Resistant Plasterboard, often referred to as "Gypfor Fire Panel," is a specialized plasterboard explicitly engineered to provide enhanced fire resistance in interior walls, ceilings, and other structural elements. Distinguished by its pink/red paper facing, this board features a high-density gypsum core fortified with glass fibre additives, which significantly improves its integrity and cohesion under high temperatures. It is an essential component in fire-rated partition systems, offering extended periods of fire protection crucial for occupant safety and property preservation.

Features

- Enhanced Fire-Resistant Gypsum Core: The core is made from a non-combustible gypsum, to which glass fibres and other fire-retardant additives are incorporated during manufacturing. These additives help the board maintain its structural integrity and slow the spread of fire by holding the core together for longer during a fire event.

- Pink/Red Paper Facing: The board is typically coated with a distinctive pink or red paper on both sides, serving as a clear visual identifier for fire-resistant plasterboard, ensuring correct product selection on site. The surface is ready for various decorative finishes (e.g., paint, wallpaper, or plaster skim) after proper preparation.

- Non-Combustible Gypsum Core: The base gypsum material is inherently non-combustible, contributing to the overall fire safety performance of the building structure.

- Tapered Edge (TE): Primarily supplied with tapered edges, which are designed for seamless jointing using tapes and fire-resistant jointing compounds, creating a smooth and invisible finish.

- Thermal Conductivity: Typically offers a thermal conductivity (Lambda, lambda) value of 0.25 W/m.K, contributing to the overall thermal performance of wall and ceiling systems.

- Easy to Cut and Install: Can be cut with a plasterboard knife and snapped for efficient installation, though its higher density may require a slightly firmer cut. It can be mechanically fixed to timber or metal stud frames or adhered using fire-resistant plasterboard adhesive.

- System Performance: Its fire resistance is achieved as part of a complete fire-rated system, including appropriate studwork, fixing methods, and fire-resistant jointing compounds. The performance duration (e.g., 30, 60, 90, 120 minutes) is dependent on the specific system construction.

Applications

Gypfor Fire Resistant Plasterboard is essential for interior applications where specific fire rating requirements must be met, including:

- Fire-Rated Partition Walls: Constructing walls that act as fire barriers between different compartments in residential, commercial, and public buildings (e.g., corridors, escape routes, stairwells, separating apartments).

- Ceilings: Used in ceiling systems to provide fire resistance and protect the structure above.

- Lift Shafts & Service Ducts: Encapsulating services and shafts to prevent the spread of fire.

- Column & Beam Protection: Forming fire-resistant enclosures around structural steelwork to maintain structural integrity during a fire.

- Areas Requiring Enhanced Fire Safety: Such as boiler rooms, plant rooms, or commercial kitchens.

- Loft Conversions: Often required for fire separation between new living spaces and existing structures.

Standards & Compliance

Gypfor Fire Resistant Plasterboard is manufactured to comply with stringent European and national standards, ensuring its quality, fire performance, and safety for use in construction.

- EN 520:2004 + A1:2009 - Gypsum Plasterboards - Definitions, Requirements and Test Methods: Gypfor Fire Resistant Plasterboard complies as a Type F plasterboard under this standard. The 'F' designation specifically indicates its enhanced core cohesion at high temperatures, contributing to its fire resistance

- Reaction to Fire (Euroclass Rating): Gypfor Fire Resistant Plasterboard consistently achieves a Reaction to Fire classification of A2-s1, d0 according to EN 13501-1.

- A2: Indicates non-combustibility with very limited contribution to fire.

- s1: Signifies very limited smoke production.

- d0: Means no flaming droplets/particles.

- This classification makes it suitable for use in applications requiring a high level of fire safety.

- Fire Resistance (System Performance): While the board itself has a Euroclass rating, the actual fire resistance period (e.g., 30, 60, 90, 120 minutes of integrity and insulation) is achieved by the complete wall or ceiling system, tested in accordance with standards like EN 1364 (for non-loadbearing elements) or EN 1365 (for loadbearing elements). Gypfor provides system details for specific fire ratings.