Description

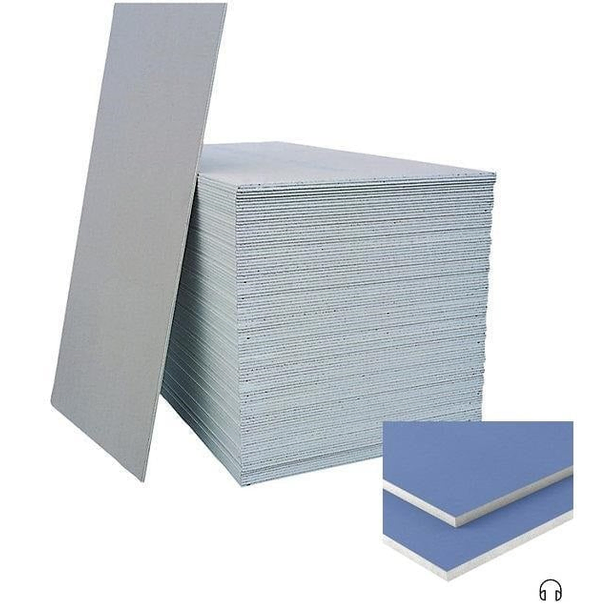

Gypfor Acoustic Tapered Edge Plasterboard (Sound Panel) - 12.5mm 8x4ft

Enhanced Sound Insulation for Quieter Spaces

Gypfor Acoustic Plasterboard, often referred to as "Gypfor Sound" or "Gypfor Sound Panel," is a specialized plasterboard engineered to significantly improve sound insulation in interior walls and ceilings. Designed for applications where noise reduction is a priority, this high-density board effectively dampens sound transmission, creating quieter and more comfortable environments in residential, commercial, and public buildings.

Features

- High-Density Gypsum Core: The core is made from a specially formulated, denser gypsum compound compared to standard plasterboard. This increased mass is crucial for enhancing acoustic performance by reducing the transmission of airborne sound.

- Blue/Grey Paper Facing: The board is typically coated with a distinct blue or blue/grey paper on both sides, making it easily identifiable as an acoustic board. This surface is ready for various decorative finishes after proper preparation (e.g., priming and jointing).

- Non-Combustible Gypsum Core: Like standard plasterboard, the gypsum core is inherently non-combustible, contributing to the overall fire safety of a building.

- Tapered Edge (TE): Primarily supplied with tapered edges, which are designed for seamless jointing using tapes and jointing compounds, allowing for a smooth and invisible finish once decorated.

- Standard Dimensions: Commonly available in thicknesses of 12.5mm and 15mm, and standard board sizes like 2400mm x 1200mm (8' x 4'). Other lengths (e.g., 2500mm, 3000mm) may also be available, providing a coverage of 2.88m² per board for the 2400x1200mm size.

- Enhanced Surface Hardness: Additives in its composition give it greater surface hardness, improving its impact resistance – a beneficial property for general durability in busy environments.

- Good Thermal Conductivity: Typically offers a thermal conductivity (Lambda, λ) value of 0.25 W/m.K, contributing to the thermal performance of a wall or ceiling system.

- Easy to Cut and Install: Can be cut with a plasterboard knife and snapped for efficient installation. It can be mechanically fixed to timber or metal stud frames or adhered using plasterboard adhesive.

- Humidity and Temperature Considerations: Not suitable for use in areas with temperatures that regularly exceed 52°C or in highly humid environments.

Acoustic Performance

- Gypfor Acoustic Plasterboard's higher density directly contributes to its superior sound reduction properties. While specific dB reduction figures depend heavily on the entire system (e.g., number of layers, cavity insulation, stud type, airtightness), a single layer of acoustic plasterboard significantly outperforms standard plasterboard. For example, a system incorporating acoustic plasterboard can achieve substantially higher airborne sound insulation (R$_{w}$) values.

Applications

Gypfor Acoustic Plasterboard is specifically designed for applications where effective sound insulation is critical:

- Partition Walls: Creating internal walls in residential (e.g., separating bedrooms, flats) and commercial buildings (e.g., offices, meeting rooms) to reduce noise transmission between spaces.

- Ceilings: Used in ceiling systems to reduce noise transfer between floors or from external sources.

- Home Cinemas & Studios: Essential for soundproofing entertainment rooms, recording studios, or music practice spaces.

- Schools & Hospitals: Ideal for classrooms, patient rooms, and corridors where acoustic comfort and privacy are important.

- Hotels & Apartments: Used to enhance acoustic privacy between individual units.

- Existing Wall Linings: Can be applied to existing walls to upgrade their acoustic performance.

Standards & Compliance

Gypfor Acoustic Plasterboard is manufactured to comply with stringent European standards, ensuring its quality, performance, and safety for use in construction.

- EN 520:2004 + A1:2009 - Gypsum Plasterboards - Definitions, Requirements and Test Methods: Gypfor Acoustic Plasterboard typically complies as a Type DI plasterboard under this standard. The 'DI' designation (referring to "high density") specifically indicates its enhanced sound insulation properties.

- Reaction to Fire (Euroclass Rating): Gypfor Acoustic Plasterboard consistently achieves a Reaction to Fire classification of A2-s1, d0 according to EN 13501-1.

- A2: Indicates non-combustibility with very limited contribution to fire.

- s1: Signifies very limited smoke production.

- d0: Means no flaming droplets/particles.

- Note: While inherently fire-resistant, acoustic plasterboard does not typically meet the highest specific "fire-rated" classes (e.g., Type F for enhanced fire resistance) unless explicitly stated for a particular variant or system.