Description

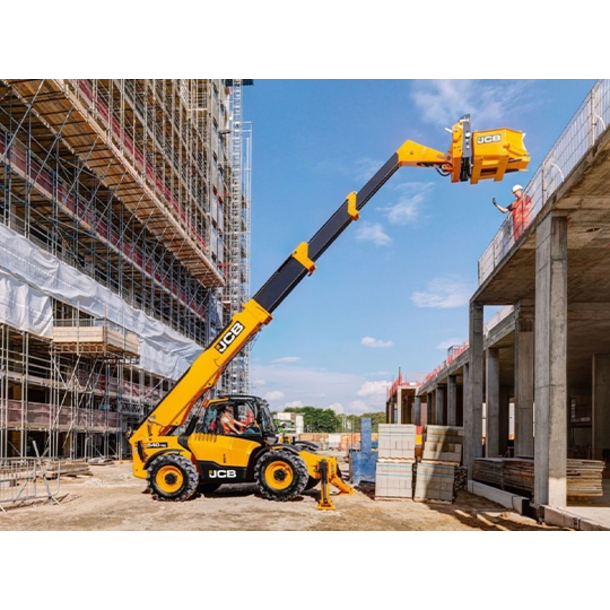

JCB 540-180 HI-VIZ Telehandler: The Ultimate in High Reach & Safety

The JCB 540-180 HI-VIZ Loadall is a class-leading telescopic handler engineered for maximum reach, capacity, and operator safety. Its groundbreaking HI-VIZ design provides unparalleled visibility, transforming productivity and significantly reducing risks on challenging construction, infrastructure, and large-scale industrial projects. This machine is built to excel where extreme height and heavy lifting are paramount.

Features

- 4.0 Tonne Max. Lift Capacity: Capable of lifting substantial loads up to 4,000 kg (4 tonnes), enabling it to handle the heaviest building materials, structural components, large concrete elements, and bulk loads with confidence and stability.

- 18 Metre Max. Lift Height: The multi-stage telescopic boom delivers an exceptional maximum lift height of up to 18 meters (59 feet). This makes it an indispensable machine for high-rise construction, placing materials on multi-story buildings, assisting with extensive scaffolding erection, and reaching over large obstacles.

- Extensive Forward Reach: Offers a maximum forward reach that typically extends to over 13 meters (42 feet), providing immense flexibility for placing materials precisely at a considerable distance from the machine, often supported by stabilizers for optimal safety and performance at full extension.

- Revolutionary JCB HI-VIZ Design for Unrivalled Visibility: This is the hallmark of the 540-180 HI-VIZ:

- Low Boom Pivot & Low Boom Profile: The boom is mounted significantly lower in the chassis compared to conventional designs and features a slender, reduced-size section. This drastically opens up the operator's rearward and three-quarter visibility over the right-hand side, a traditional and dangerous blind spot on telehandlers.

- Direct Glazing & Large Roof Screen: The cab boasts extensive, direct glazing and a large, unobstructed roof screen, providing superb all-round visibility of the load, surroundings, and working area.

- Strategic Placement of Components: All elements are meticulously placed to minimize obstructions, ensuring the operator has the clearest possible view, enhancing safety during travel and load handling.

- Optional Camera & Radar Systems: Can be equipped with reversing cameras and JCB's advanced Pulse Radar systems for enhanced pedestrian and obstacle detection, further bolstering site safety.

- Powerful & Efficient JCB DieselMAX Engine: Powered by JCB's highly respected DieselMAX engine, typically offering power outputs around 81 kW (109 hp) or 97 kW (130 hp). These engines are designed to meet stringent EU Stage V emissions regulations without the need for complex DPF regeneration or AdBlue (DEF) systems on some configurations, simplifying maintenance and reducing running costs.

- Productive Drivetrain & Manoeuvrability:

- Powershift Transmission: Features a smooth and efficient Powershift transmission, allowing for seamless, on-the-move gear changes for faster cycle times and travel speeds up to 29 km/h (18 mph).

- Permanent 4-Wheel Drive: Ensures excellent traction and robust performance across challenging and varied terrains, including muddy, soft, or uneven ground conditions.

- 3 Steering Modes: Provides exceptional agility with 2-wheel steer for road travel, 4-wheel steer for tight turning circles, and crab steer for precise parallel movement, invaluable for navigating congested sites or working alongside obstacles.

- Advanced Safety Features: JCB integrates multiple layers of safety mechanisms:

- Automatic Eye-Level Load Moment Indicator (LMI): Continuously monitors the machine's forward stability, providing clear audio-visual warnings and proportional boom control to prevent overloading and ensure safe lifting operations.

- Hose Burst Check Valves (HBCVs): Fitted to hydraulic rams as standard, preventing boom collapse in the event of hose failure.

- ROPS/FOPS Certified Cab: The operator's cab is fully certified to Roll-Over Protective Structure (ROPS) and Falling Object Protective Structure (FOPS) standards for maximum operator protection.

- Stabilizers: Integral to its high-reach capability, the extendable stabilizers (outriggers) provide a solid, stable base for safe lifting to maximum heights and reaches.

- Operator Presence Switch: Disables drive and hydraulic functions if the operator is not seated, preventing accidental movement.

- Robust Strength & Durability:

- One-Piece Fully Welded Chassis: Provides an exceptionally strong and rigid foundation for the machine.

- Heavy-Duty U-Shaped Boom Pressing: With fully welded closing plates and internally routed hoses, maximizing durability and protecting vulnerable components from site damage.

- Designed and tested to withstand the most extreme demands of continuous, heavy-duty operation.

- Superior Operator Comfort:

- Spacious & Ergonomic Cab: One of the largest and most comfortable cabs in its class, offering generous space, excellent direct glazing for visibility, and intuitive, ergonomic controls, significantly reducing operator fatigue over long shifts.

- Adjustable Steering Column & Suspension Seat: Allows operators to find their ideal driving position.

- New Instruments & Hi-Res TFT Screen: Provide clear, automotive-style information and diagnostics.

- Single-Lever Controls: Often available, providing intuitive and precise control of boom and attachment functions.

- JCB LiveLink Telematics: Standard on many models, this advanced telematics system offers real-time data on machine location, operating hours, fuel consumption, service alerts, and performance reports, enabling efficient fleet management, proactive maintenance, and reduced downtime.

- Versatile Attachment Capability: Utilizes the JCB Q-Fit carriage, allowing for quick and secure attachment changes. Compatible with a vast range of accessories including various forks, rehandling buckets, jibs, waste handlers, and specialized work platforms, maximizing its utility across diverse tasks.

Applications

The JCB 540-180 HI-VIZ Telehandler is an indispensable machine for the most demanding high-reach and high-capacity applications:

- High-Rise Construction: Lifting and placing materials on multi-story building sites, including structural steelwork, pre-cast concrete, glazing, and facade elements.

- Large Infrastructure Projects: Supporting bridge construction, major roadworks, and complex civil engineering where materials need to be moved over significant distances or heights.

- Roofing & Cladding: Efficiently lifting large quantities of roofing materials, insulation, and cladding panels to extreme heights.

- Scaffolding & Access: Lifting heavy scaffolding components and positioning large work platforms for elevated access (with appropriate attachments and safety measures).

- Industrial & Port Operations: Handling heavy cargo, loading/unloading large vessels or trains, and managing bulk storage in large industrial yards.

- Demolition: Controlled placement of demolition attachments and efficient handling/removal of debris from large demolition sites.

* Brand & model may vary depending on availability, if a specific model is required, please request in additional notes at point of order.