Description

Toyota Tonero LPG Forklift (2.5T Gas Powered): Power, Productivity & Safety

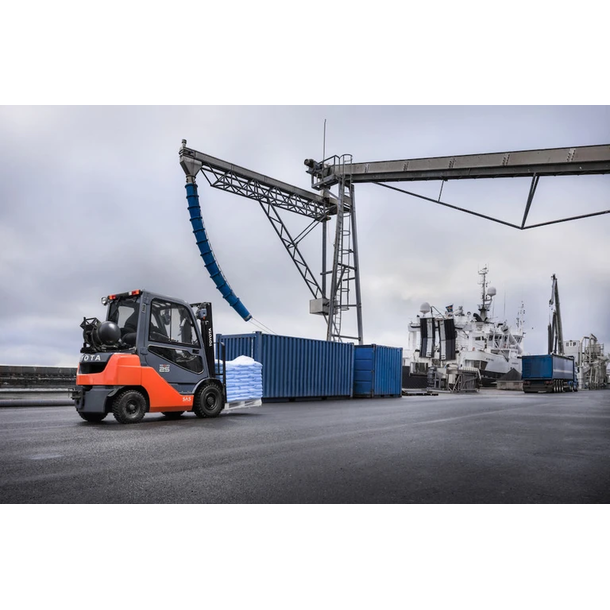

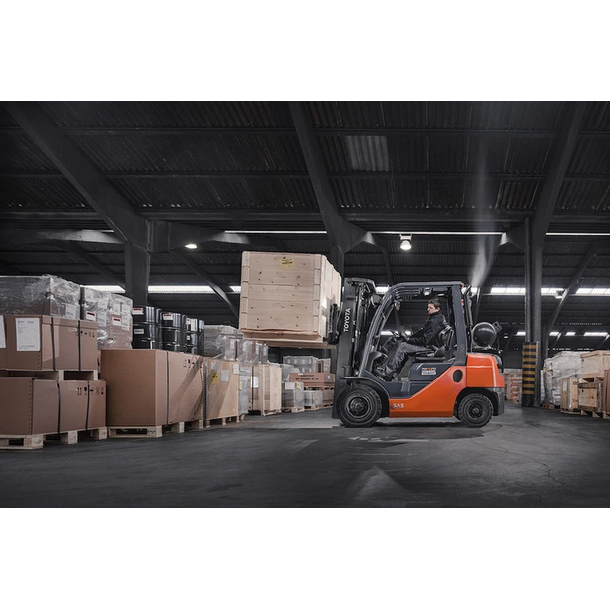

The Toyota Tonero 2.5-tonne LPG forklift is a versatile and efficient engine-powered counterbalance truck engineered to excel in diverse material handling tasks. Powered by a robust and fuel-efficient industrial LPG (Liquefied Petroleum Gas) engine, this forklift delivers strong performance, fast acceleration, and the flexibility to operate effectively in both indoor and outdoor environments.

Features

- 2.5 Tonne Load Capacity: Capable of lifting and transporting loads up to 2500 kg (2.5 tonnes) with a standard load centre of 500 mm, making it suitable for handling a wide range of palletised goods and heavier items.

- Powerful Toyota Industrial LPG Engine: Equipped with an in-house designed Toyota industrial engine (e.g., Toyota 4Y-ECS or similar for LPG). These engines are specifically developed for forklift applications, ensuring quick acceleration, optimal fuel efficiency, and compliance with the latest emissions regulations (e.g., surpassing Stage V requirements).

- Choice of Transmission: The Tonero series often offers a choice between:

- Torque Converter Transmission: Provides a smooth and intuitive driving experience, ideal for applications requiring longer travel distances and consistent speed control, such as transporting goods across large warehouses.

- Hydrostatic Transmission (HST): Offers powerful engine braking and acceleration, quick changes of direction, and often independent drive and lift functionality, making it highly effective for intensive loading/unloading tasks (e.g., lorries) and operations requiring precise control.

- Toyota System of Active Stability (SAS): A cornerstone of Toyota's safety philosophy, SAS is a unique and advanced active system that continuously monitors the forklift's stability. It acts proactively to help prevent accidents by:

- Active Mast Function Control: Limits forward tilt of the mast based on load weight and height, and controls backward tilt speed, reducing the risk of dropped loads or tip-overs.

- Active Steering Synchronizer: Synchronizes the steering wheel position with the actual wheel position for safer and more comfortable driving.

- Fork Levelling Control: Allows the operator to easily level the forks with the push of a button for quicker and safer pallet entry.

- Speed and Acceleration Control: Limits drive speed with load at height and controls sudden acceleration to reduce the risk of load spills.

- Outstanding All-Round Visibility: Designed with a clear-view mast and overhead guard, a low dashboard, and optimized chassis design, providing operators with excellent visibility of the fork tips, load, and surrounding environment, enhancing safety and productivity.

- Ergonomic Operator Comfort: The spacious operator compartment is designed for long shifts, featuring:

- A fully adjustable Operator Restraint System (ORS) seat with side-wings and lumbar support.

- Ample legroom and an adjustable tilt steering column.

- Intuitive controls (choice of traditional levers, mini-levers, or joystick).

- An all-in-one multi-function display providing essential information.

- Robust Build for Durability: Constructed with high-quality components and subjected to rigorous testing, the Tonero is built to withstand the demands of heavy-duty, daily operation, ensuring long-term reliability and low service costs.

- Excellent Manoeuvrability: With a good turning radius and responsive power steering (often load-sensing), the 2.5T Tonero is highly manoeuvrable, allowing it to operate efficiently in confined spaces and navigate tight aisles.

- Low Noise and Vibration: Designed to minimize truck noise and vibration, contributing to a more comfortable and less fatiguing experience for the operator.

Applications

The Toyota Tonero LPG Forklift 2.5T is a versatile and reliable choice for a broad spectrum of material handling needs, including:

- Warehousing & Logistics: Loading/unloading trailers, stacking and retrieving goods in racking systems (with appropriate mast).

- Manufacturing & Production: Moving raw materials, finished goods, and equipment within factory floors.

- Construction Sites: Handling building materials, tools, and equipment on site (often with pneumatic tires for rough terrain).

- Distribution Centers: Efficiently moving goods between receiving, storage, and dispatch areas.

- Retail & Wholesale: Managing stock in large retail outlets or wholesale depots.

- Timber Yards & Lumber Mills: Handling heavy timber loads.

- Agriculture: Various material handling tasks on farms and agricultural sites.

* Brand & model may vary depending on availability, if a specific model is required, please request in additional notes at point of order.