Description

Armorgard CuttingStation SS7X: Revolutionising On-Site Cutting Safety and Efficiency

The Armorgard CuttingStation SS7X is an innovative, all-in-one mobile workstation meticulously designed to transform on-site material cutting. It eliminates the need for a separate cutting room by creating a dedicated, safe, and controlled environment for cutting lengths of materials such as conduit, timber, cable tray, and pipe. The "X" in SS7X signifies its integrated extraction and air filtration system, making it the safest and most compliant choice for professional cutting operations.

Features

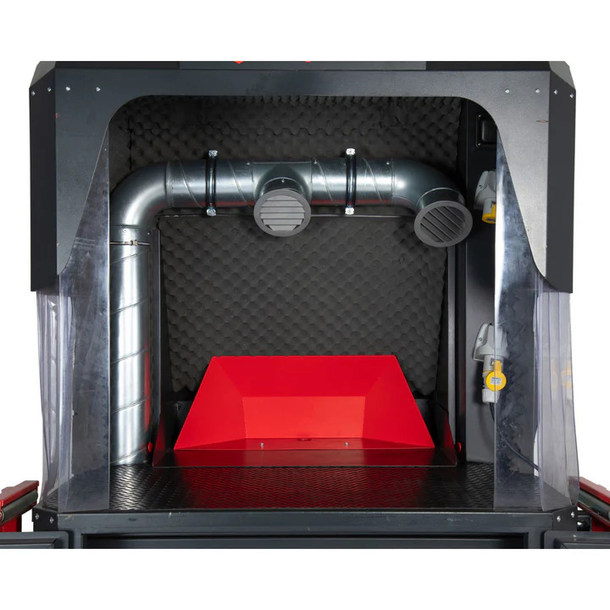

- Integrated Dust and Particulate Extraction (Xtract System): The standout feature. The SS7X includes a powerful Husqvarna A1000 air scrubber filtration system (or similar high-performance unit). This system effectively captures and filters dust and respirable particulates generated during cutting, significantly reducing operator exposure to harmful airborne substances and contributing to a healthier working environment. It's tested and certified for use as both an air cleaner and a negative air machine, utilizing HEPA class H13 filters (99.99% efficiency at 0.3 microns).

- Superior Noise Reduction: Equipped with sound-deadening, fire-rated foam and chamfered corners to minimize noise pollution. This can reduce noise by up to 20 decibels, significantly benefiting both the operator and other personnel on site.

- Spark Containment: Features PVC curtains to effectively contain sparks and debris generated during cutting, reducing fire hazards and protecting nearby workers.

- Optimised Working Environment:

- Improved Lighting: New and strategically positioned internal lighting ensures a well-lit cutting area, increasing visibility and productivity, especially in low-light conditions.

- Rubber Matting: A durable rubber mat reduces vibration (minimizing Hand-Arm Vibration - HAV) and provides a non-slip surface for the cutting tool.

- Ergonomic Working Height: Positions the cutting tool at a safe and comfortable working height, reducing back strain and the risk of tripping over materials cut on the floor.

- Versatile & Expandable Work Area:

- Extendable Support Arms: Features improved extendable support arms with four different configurations, making it quicker and easier to adjust and stabilize longer lengths of material.

- Extendable Back Panel: Provides extra workspace specifically designed to accommodate larger mitre saws, enhancing versatility.

- Cutaway Sides: Allow for easier handling and feeding of longer material lengths through the station.

- Secure & Mobile:

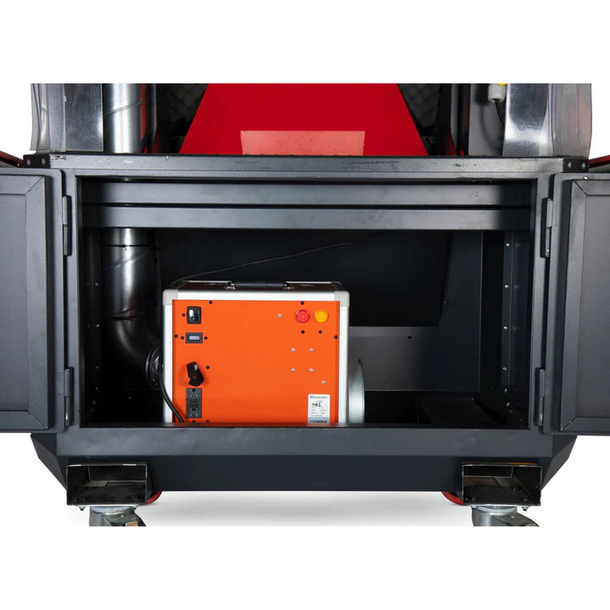

- Integrated Secure Cabinet: A robust, lockable cabinet (typically with a 5-lever deadlock) beneath the workbench area provides secure storage for tools and accessories when not in use.

- Heavy-Duty Mobility: Fitted with heavy-duty all-swivel castors for easy movement around site. It also includes forklift pockets and crane lifting eyes (often as optional extras) for safe and efficient relocation by plant machinery.

- Integrated Power Supply: Features a recessed 110V inlet power supply and two internal 110V sockets, providing convenient power for your cutting tools and the integrated extraction unit.

- Swarf Collector: Includes an internal swarf collector with a dust extractor connection point to manage debris effectively.

- Robust Construction: Manufactured from 1.5mm powder-coated steel and aluminium, ensuring high durability and resistance to wear and tear in demanding site conditions.

- External Dimensions (L x W x H):

- Standard: 1390mm x 780mm x 1900mm (or 1360 x 770 x 1905mm)

- Extended: Up to 3225mm x 1090mm x 1900mm (with support arms and back panel extended)

- Internal Dimensions (W x D x H):

- Top (with extended back): Approx. 1125mm x 995mm x 1000mm

- Base Cabinet: Approx. 1125mm x 710mm x 550mm

- Weight: Approx. 200 kg

Applications

The Armorgard CuttingStation SS7X is an essential piece of equipment for:

- Construction Sites: Cutting conduit, cable tray, Unistrut, timber, pipe, trunking, and various other linear materials.

- Manufacturing Facilities: For safe, localized cutting operations.

- Workshops: Providing a dedicated and controlled cutting environment.

- Renovation & Refurbishment Projects: Minimizing mess and hazards in occupied or sensitive areas.

- Anywhere where safe, compliant, and contained cutting of materials is required.

* Brand & model may vary depending on availability, if a specific model is required, please request in additional notes at point of order.