Description

Fairport HFBS65 Hydraulic Block Splitter: Powerful, Precise & Dust-Free Masonry Splitting

The Fairport HFBS65 is a heavy-duty hydraulic block and slab splitter, engineered for the quick, safe, and efficient sizing of a wide range of masonry and concrete products. Manufactured by Fairport, a trusted UK brand in construction equipment, the HFBS65 stands out as a superior alternative to traditional abrasive cutting methods, providing a dust-free and quiet solution for professional landscapers, builders, and paving contractors.

Features

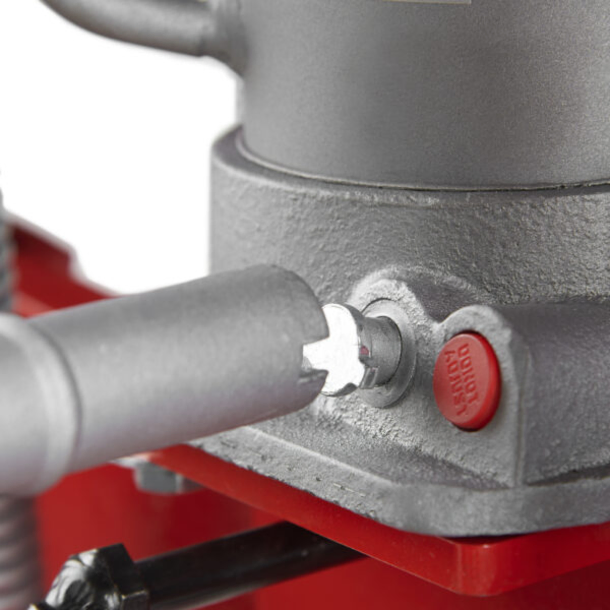

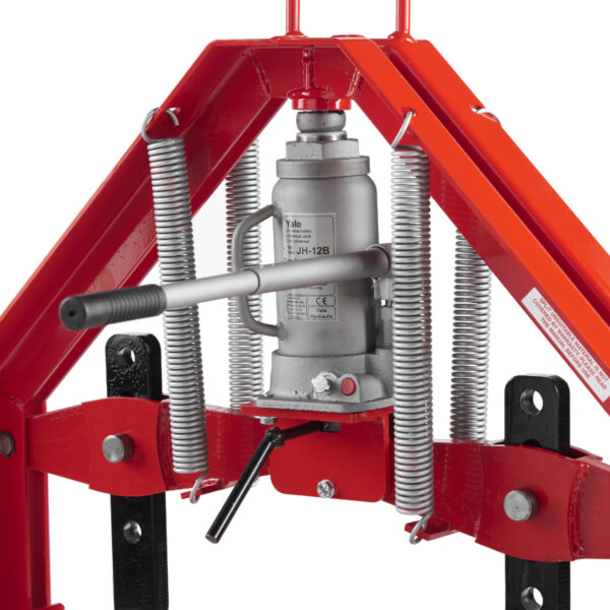

- Exceptional Splitting Force (20+ Tonnes): Powered by a 12-tonne hydraulic piston, the HFBS65 multiplies this force to deliver over 20 tonnes of splitting power at the cutting edges. This immense force allows it to effortlessly split even the hardest materials, including dense concrete slabs, kerbstones, and paving blocks, in a matter of seconds.

- Wide Cutting Capacity:

- Max Cut Width: Accommodates materials up to 650mm (approximately 25.5 inches) wide, making it suitable for standard paving slabs and larger blocks.

- Max Cut Height: Capable of splitting materials up to 235mm (approximately 9.25 inches) in height, covering a broad spectrum from thin patio slabs to substantial building blocks and kerbs.

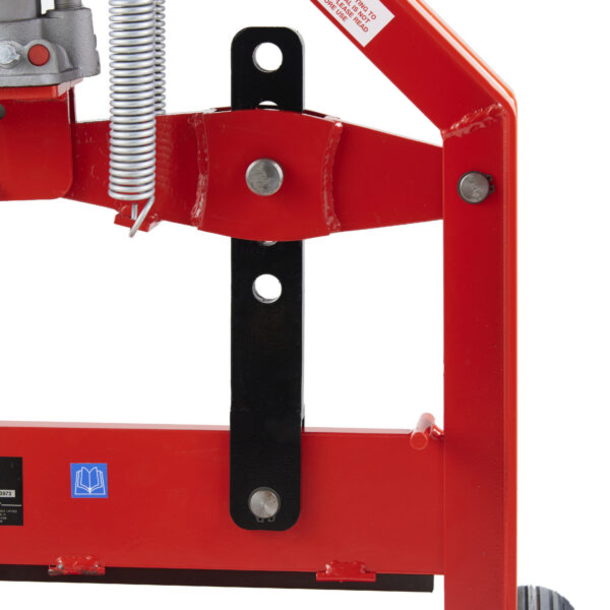

- Adjustable Blade Height: The blade height can be easily adjusted to precisely accommodate various "flat-faced" masonry products, ensuring optimal contact and a clean split regardless of material thickness.

- Dust and Noise Free Operation: A significant advantage over petrol or electric cut-off saws. The HFBS65 operates by splitting rather than grinding, eliminating airborne dust (which includes hazardous silica) and significantly reducing noise pollution. This makes it ideal for use in residential areas, public spaces, and other environments where health and safety regulations or noise restrictions are paramount.

- Heavy-Duty Construction: Built to withstand the rigours of daily site use, the HFBS65 features a robust, heavy-weight steel frame and durable components. This ensures long-term reliability and resistance to the harsh conditions encountered on construction sites.

- Reversible Blades with 3 Cutting Edges: Both the upper and lower blades are triangular and reversible, providing three usable cutting edges per blade. This extends the life of the blades considerably, reducing the frequency of replacements and overall running costs.

- Large Work Supports: Equipped with generous work supports that securely hold the material in place during the splitting process. This helps to maintain a precise vertical cut and enhances operator safety and accuracy.

- Integrated Wheels for Easy Transport: Fitted with sturdy, integrated wheels, the HFBS65 can be easily moved around the job site by a single person, simplifying positioning and reducing physical strain.

- Designed for Parallel-Faced Materials: Specifically optimized for cutting masonry and concrete products with parallel faces, such as standard paving blocks, slabs, kerbstones, and bricks. It is not suitable for splitting irregular natural stone or materials without parallel faces, as this can lead to blade deflection or damage.

Applications

The Fairport HFBS65 Hydraulic Block Splitter is an indispensable tool for:

- Block Paving Installation: Precisely sizing paving blocks for edges, curves, and infill areas, achieving a professional finish.

- Slab Laying: Cutting concrete and natural stone (with parallel faces) paving slabs to exact dimensions for patios, pathways, and general landscaping.

- Kerbstone Installation: Efficiently splitting kerbstones for accurate placement and transitions.

- Brick and Block Work: Sizing bricks and concrete blocks for various building applications.

- Landscaping Projects: Any project requiring clean, precise cuts on masonry materials without the dust and noise of traditional saws.

- Urban & Residential Work: Its quiet, dust-free operation makes it ideal for sites close to homes, businesses, or in environmentally sensitive areas.

Safety Considerations

- Always wear appropriate Personal Protective Equipment (PPE), including eye protection, sturdy gloves, and safety footwear.

- Ensure the splitter is placed on a stable, level surface before use.

- Keep hands and fingers clear of the blades and splitting mechanism during operation.

- Never attempt to split materials that exceed the machine's maximum dimensions or are not "flat-faced".

- Follow the manufacturer's guidelines for hydraulic system maintenance and general care.

* Brand & model may vary depending on availability, if a specific model is required, please request in additional notes at point of order.