Description

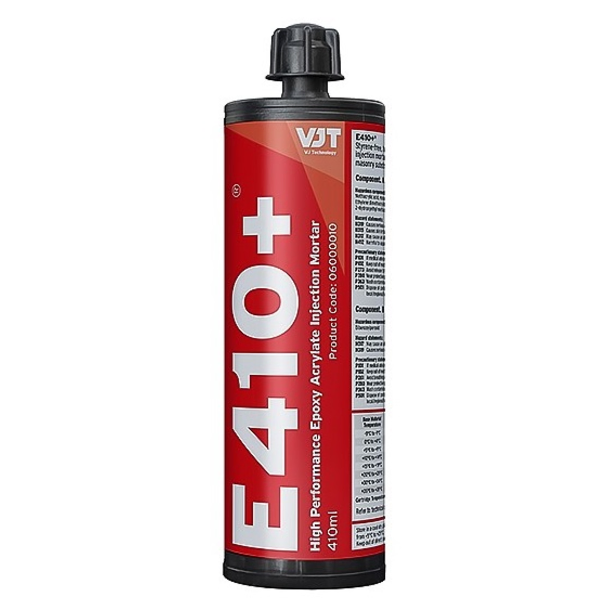

VJ Technology E410+ Chemical Resin – 410 ml Cartridge

E410+ is a high-performance, two-component epoxy‑acrylate injection resin delivered via a coaxial cartridge. Activated through a static mixer nozzle, it cures into a dense, robust mortar suitable for anchoring threaded rods, rebar, sleeves, and lintels in both concrete and masonry—dry or wet conditions, including overhead locations.

Features

- Cartridge-delivered 2-component resin (resin + hardener) activated on extrusion for consistent mixing and application control.

- Approvals for non-cracked concrete (C20/25–C50/60) and masonry substrates (including solid and hollow blocks); suitable for overhead-use.

- Low-odour, high chemical resistance epoxy-acrylate formulation—safer and cleaner than traditional solvent-based anchors.

- Long shelf life & reuse-friendly: Cartridges can be resealed and used until expiry (~18 months) by replacing sealed nozzles.

- High-performance under constrained conditions: Allows small edge distances and close anchor spacing in tight or loaded installations.

Applications

- Chemical anchoring of threaded rods (M8–M24), reinforcing bars, and internal sleeves.

- Secure fixing of façade elements, consoles, cable trays, piping, metal profiles, sanitary fittings, roof structures, and timber elements.

- Masonry and concrete anchoring, including solid or hollow blocks with screw-on sleeves for hollow units.

- Overhead and vertical installations, enabling chemical anchoring in ceilings or walls with gravity-limited resin flow.

Standards & Compliance

- ETA & UKTA approvals for non-cracked concrete (ETA 12/0570) and masonry (ETA 17/0378), certified by UK Technical Assessments.

- CE & UKCA marked under CPR, with DoP reference 1343-CPR-M 532-3/4-CE and UKTA‑0836‑22 approvals.

- Conforms to EAD 330332 (concrete) and EAD 330076 (masonry) standards per ETA certification.

- Reaction to fire Classification A1 (non-combustible anchor system), supporting structural fire integrity.

- Performance parameters defined: Comprehensive characteristic resistances (tension, shear, displacement) across rod sizes M8–M24 provided per BS EN 1992‑4 and ETAG 029.