Description

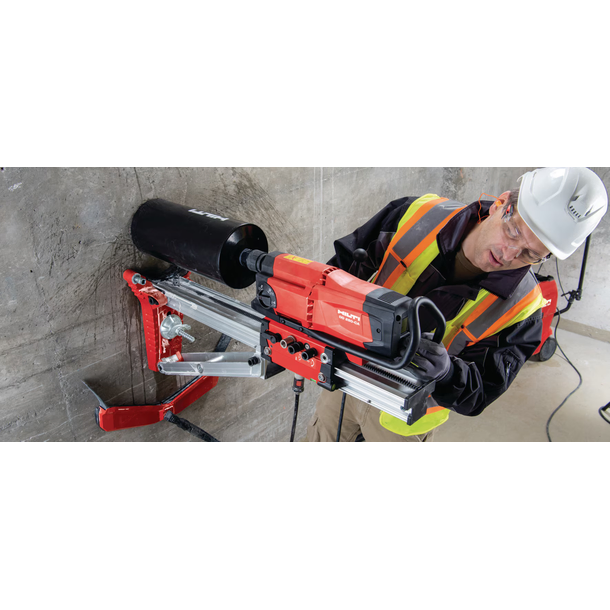

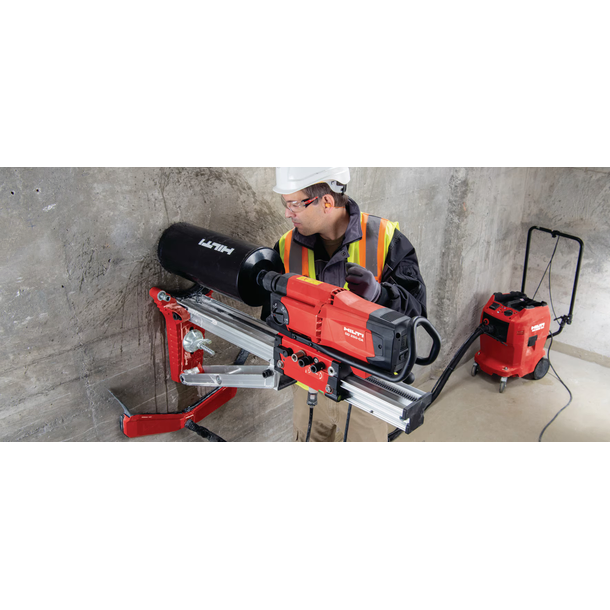

Hilti DD 250 Diamond Core Drill (Rig-Based): Unrivalled Precision & Power for Large Diameter Coring

The Hilti DD 250 is an advanced, heavy-duty electric diamond coring system engineered for exceptionally precise and efficient drilling of small to very large diameter holes in concrete, reinforced concrete, and asphalt. Designed primarily for rig-based operation, this system delivers consistent high performance for demanding applications where clean, accurate penetrations are paramount.

Features

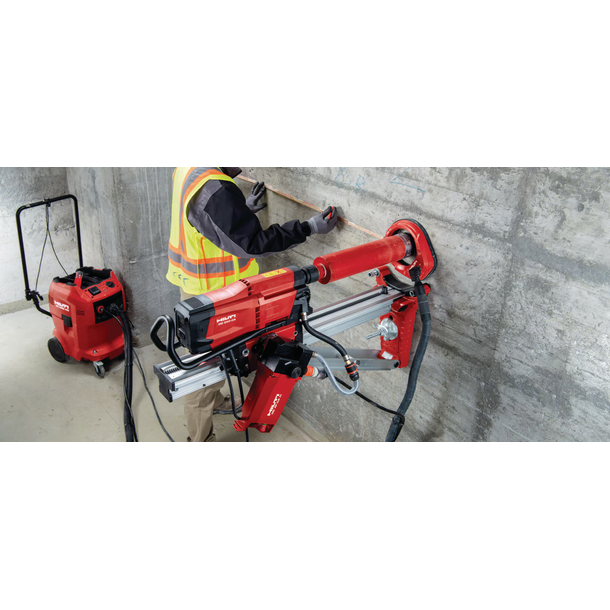

- Extremely Wide Drilling Diameter Range: The DD 250 is capable of drilling holes from 12mm up to 500mm (0.5" to 20") in diameter. This unparalleled versatility means a single system can handle a vast array of tasks, from small anchor holes to large penetrations for ducts, pipes, and cables, reducing the need for multiple tools.

- Powerful & Air-Cooled Drive Unit: Features a robust, air-cooled drive unit with a high-performance motor (e.g., 3.2 kW). This heavy-duty design ensures sustained performance even during continuous drilling and in challenging conditions, preventing overheating.

- Four-Speed Gearing: Equipped with a four-speed gearbox (e.g., 240, 580, 1160, 2220 RPM). This allows the operator to select the optimal speed and torque for different core bit diameters and base materials, maximizing drilling efficiency and extending core bit life.

- Real-time Information Display: A sophisticated digital display provides crucial real-time feedback to the operator. This includes:

- Digital Spirit Level: For precise horizontal and vertical alignment of the drill stand.

- Gear Selector: Indicates the currently selected gear.

- Power Control Function: Provides visual feedback on applied pressure, helping the operator maintain optimal drilling pressure for maximum performance and minimum core wear (e.g., yellow for too low pressure, green for optimal, red for too high).

- Trip Counter & Running Time Counter: For productivity monitoring.

- Service Messages: Easy-to-understand messages for maintenance or troubleshooting.

- "Hole-Starting" Function: A low-vibration, low-speed mode specifically designed to facilitate smooth and precise hole starting with large-sized core bits, preventing walking or skidding.

- Modular Rig-Based System: The DD 250 operates as part of a rig system, typically including:

- Drill Stand (e.g., DD-HD 30-CA): Robust and stable stand for precise drilling, often with features like an integrated vacuum/anchor base plate for secure mounting.

- Feed Unit: Manual or, in advanced "CA" models, an optional Cut Assist (Autofeed) unit (DD AF-CA H) for fully automated drilling, which detects the surface, optimizes speed and water flow, and even adjusts when cutting through rebar, significantly boosting productivity and allowing operators to perform other tasks.

- Extension Bars: For deep drilling, 300mm extension bars can be used with core bits over 400mm long.

- Wet and Dry Drilling Capabilities: The system supports both wet and dry drilling modes, providing flexibility for different applications and dust management needs. Wet drilling is optimized for concrete and reinforced concrete to cool the bit and suppress dust, while dry drilling can be used for masonry or in situations where water is not feasible.

- Water Management System Integration (Optional): Newer models often feature Bluetooth connectivity to steer Hilti's water management systems (e.g., DD-WMS 100 BLE) and autofeed units, enabling a fully autonomous drilling process.

- Robust & Durable Design: Built with a heavy-duty drive unit and sturdy components, the DD 250 is designed to withstand the rigours of continuous, demanding job site use.

- Low Vibration: While powerful, the rig-based operation and machine design contribute to low vibration levels at the operator's hands (e.g., as low as 2.5 m/s² for wet drilling), enhancing user comfort and safety.

Applications

The Hilti DD 250 Diamond Core Drill is an essential tool for:

- Large-Diameter Penetrations: Creating precise openings for ducts, pipes, cables, and ventilation systems in concrete walls and floors.

- Stitch Drilling: For creating large breaches or openings by drilling overlapping holes.

- Service Entries: Coring holes for the installation of utilities and service lines.

- Structural Modifications: Drilling for anchors, rebar, or to create openings in structural concrete.

- Deep Hole Drilling: For applications requiring exceptionally deep penetrations in various materials.

- Commercial & Industrial Construction: Widely used in large-scale building projects, civil engineering, and infrastructure work.

- Renovation & Demolition: For controlled removal of concrete sections.

* Brand & model may vary depending on availability, if a specific model is required, please request in additional notes at point of order.